Select a Language

Americas (AM)

Europe, Middle East, Africa (EMEA)

- British English (United Kingdom)

- Italian (Italy)

- French (France)

- Spanish (Spain)

- German (Deutschland)

Asia Pacific (APAC)

By Industry

- Alternative Proteins

- Apparel and Accessories

- Automotive

- Bakery and Snacks

- Beverages

- Building & Construction

- Cheese & Dairy Foods

- Consumer Goods

- Electronics

- Food Retail & Case Ready

- Fresh Beef, Pork & Lamb

- Fresh Beef, Pork and Lamb Packaging Solutions

- Fresh Produce

- Frozen Foods

- Fulfillment & E-Commerce

- Healthcare

- Industrial Parts

- Liquid Food Products

- Manufacturing

- Meal Kit Packaging

- Medical & Pharmaceutical

- Pet Care

- Poultry

- Ready to Eat Meals

- Seafood

- Smoked & Processed Meats

- Wine & Spirits

Main Menu

Explore Our Products

Food Packaging

- Bag-in-Box

- Barrier Bags

- Bulk liners (IBC)

- Chub Packaging

- Dispensers and Taps

- Dispensing Pouches

- Easy-Open Shrink Bags

- Form-Fill-Seal Films

- Forming Webs

- Lid Films

- Non-Barrier Bags

- Non-Forming Webs

- Overwrap Films

- Plastic Bottles

- Pre-Opened Bags

- Preformed Food Trays

- Tea Urn Liners

- Vacuum Skin Packaging

Protective Packaging

- Bubble Bags

- Bubble Bundles

- Fabricated Foams

- Films, Bags, and Pouches

- Flooring Underlayment

- Inflatable Pillows

- Inflatable Cushioning

- Inflatable Pouches

- Light Cushioning

- Paper Mailers

- Paper Bubble Mailer

- Paper Pack Station Solutions

- Paper Wrapping Solutions

- Performance Inflatables

- Poly Mailers

- Recycled Bubble

- Recycled Content Inflatable Air Pillows

- Recycled Inflatable Cushioning

- Retention & Suspension

- Shrink Films

- Surface Protection Foams

- Temperature Assurance Liners, Bags & PUR

Protective Equipment

- AUTOBAG® Brand Certified Rebuilt Equipment

- AutoLabel Thermal Transfer Ribbon

- Automated Mailers

- Bagging and Printing Systems

- Bagging Systems

- Cartoning Systems

- Conveyors, Counters, and Scales

- Inflator Systems

- Instapak® Expanding Foam Bags and Equipment

- Paper Systems

- Printers

- Shrink Systems

- Side Pouch Systems

Blog

- The True Cost of Damage

- 3 Ways a Preventive Maintenance Plan Can Save Food Processors Money

- Connectivity: The Modern Age Of Manufacturing Technology

- Are Your Recycling Efforts a Waste?

- 5 Pitfalls to Avoid When Automating Your Packaging Hall

- Case-Ready Packaging Helps Offset Uncertainty

- Closing the Loop with Advanced Recycling

- Dinner on the Doorstep: A New Age of Grocery Shopping

- E-Commerce Demand Drives Change

- How Direct-to-Consumer Brands Can Improve The Online Delivery Experience With Packaging

- Join Us in the Lab

- Limited Touchpoints Ease Consumer Concerns

- Net Zero Emissions for Automotive Packaging

- Online Shopping Goes High-Tech — and High Risk

- Package Designs That Drive Change

- Paper Remains Top Pick for Recyclable Packaging

- Questions for ODMs When Selecting a Packaging Supplier

- Return Logistics Shouldn’t Be an Afterthought for Online Retailers

- Shipping Trends Favor Parcels, Not Pallets

- Sustainability Impact of E-Commerce Packaging

- Sustainability in Seafood: Emphasized Demands and Redefined Standards

- Tackle Dimensional Weight by Rethinking the Box

- The Changing Face of the Retail Grocery Shopper

- Unboxing: The Power of Packaging

- Unsealing Food Technology to Feed the World

- What Is Smart Packaging?

- 4 Reasons to Switch From Rigid to Flexible Packaging

- Sustainable Protein Packaging Starts With Trays

- Packaging Mistakes to Avoid

- Don't Let Packaging Ruin Your Reputation

- How Automation in Food Processing Improves Predictability

- Top 5 Trends for Case-Ready Meat Packaging

Main Menu

Explore Our Company

Main Menu

Explore Our Services

AUTOBAG® Services and Support

- Advanced Customer Training

- AUTOBAG® Product Resource Library

- AutoLabel Software Tools and Support

- Customer Service

- Custom Bagging Machine Applications

- Custom Engineering and Integrated Systems

- Factory Service Repair Center

- Field Service and Preventive Maintenance

- Financing and Payment Options

- Graphics, Art & Imaging for Custom Branded Bag Packaging

- Systems Advantage: The Total Systems Approach to Bag Packaging

- Technical Phone Support

Give us a call

Protective Packaging

Our innovative solutions help brands and retailers protect their products, increase efficiency, and enhance sustainability throughout the global supply chain.

Protective Products & Packaging Materials

Equipment Solutions for Protective Packaging

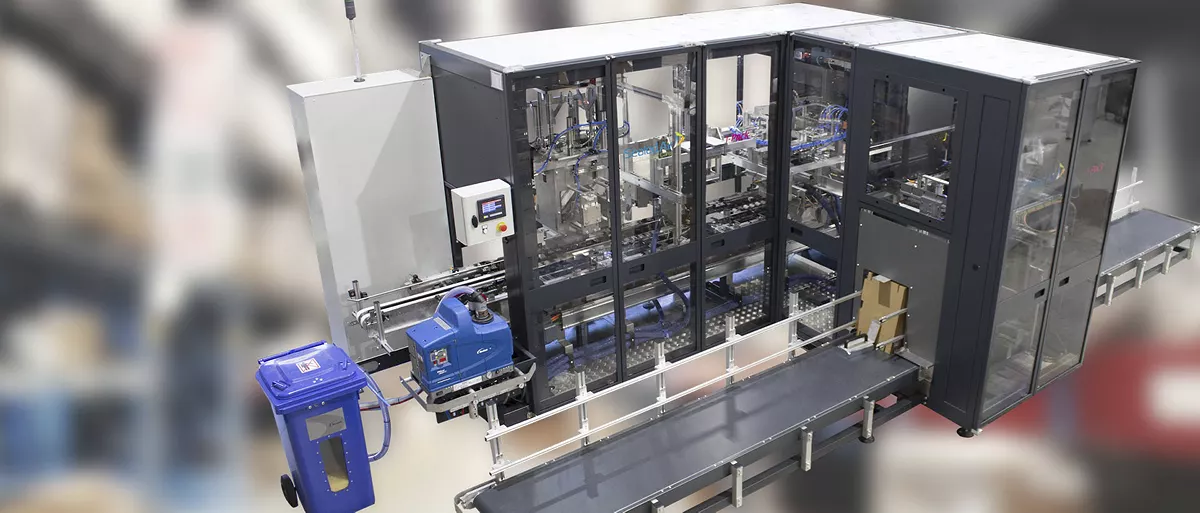

Automated Cartoning Systems

Rightsize technology helps minimize waste and reduce freight costs by eliminating the need for void fill.

View Solution

Automated Mailer Systems

Increase throughput and optimize labor by automatically adjusting the length and width of each package.

View Solution

Bagging Systems

Optimize flexibility for e-commerce order fulfillment with next-bag-out printing and labeling.

View Solution

Foam-In-Bag Systems

Get foam-filled bags on demand without the need for manual mixing or individual bag loading.

View Solution

Inflatable Void-Fill System

The BUBBLE WRAP® brand inflatable void-fill system produces air pillows on demand.

View Solution

Shrink Wrap Machines

Our shrink wrappers include features, speeds, and options that are ideally suited for containment, bundling, and display.

View Solution

Additional Resources

The True Cost of Damage

Selecting the right packaging is key to preventing damaged goods throughout distribution and shipping. When products arrive to consumers broken or damaged, the impact can be far greater than an upset customer. Learn more about the true cost of damage and the environmental impact with our infographic.